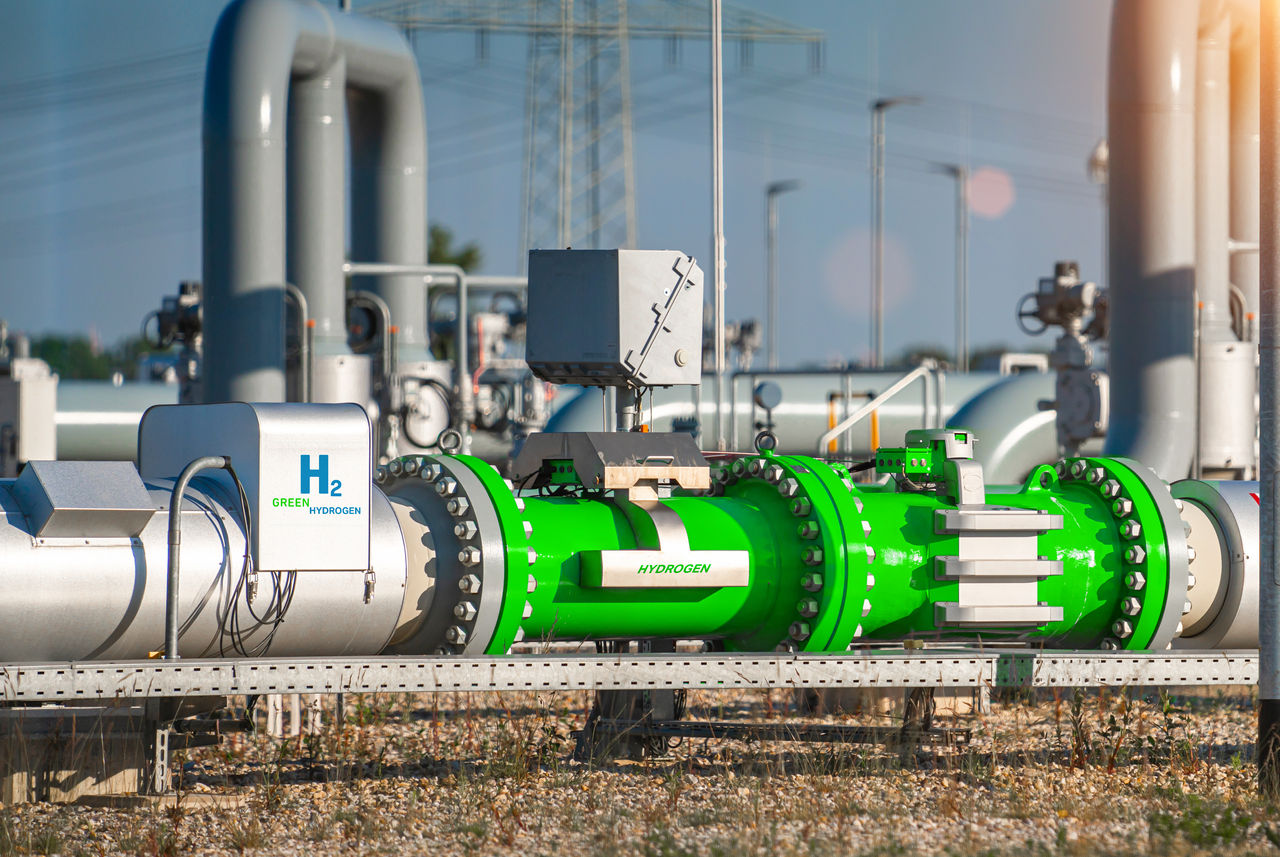

ERIKS Hydrogen Solutions: Pioneering a Greener Future

Hydrogen stands at the forefront of the clean energy transition. Not just a clean fuel source, hydrogen’s versatility is driving innovations and holds a potential to decarbonize a vast range of sectors – from transport to energy-intensive industries, from power generation to residential heating.

CASE STUDY

Customer: A large European Electrolyzer manufacturer

Specific alkaline electrolyzers produce hydrogen in cells, consisting of an anode, a cathode and a membrane in between. These cells are connected in series to form a stack. Proper sealing of the membrane itself and between the cells is crucial for safe and efficient operation. The customer turned to ERIKS because they needed to improve the performance of their seals.

Products Engineered for H2-Readiness

Sealing & Polymer

ERIKS specializes in innovative sealing solutions, crucial for the optimal and safe performance of various end products. We offer end-to-end services including product and material development, compounding, and in-house manufacturing. Our expertise is particularly strong in addressing technical challenges related to hydrogen applications.

Gaskets

Our gaskets promise reliability under rigorous conditions. Looking for innovative H2-compatible gaskets? We can custom produce them in-house swiftly.

Flow Control

Precision and reliability define our products, even under extreme conditions. Our valve-automation facilities cater to demanding market needs and we specialize in creating custom solutions tailored for unique applications.

Industrial & Hydraulic Hoses

ERIKS offers premium hoses and compensators from world-renowned manufacturers. Whether you seek standard or custom solutions for H2 applications, our specialists are ready to assist.

Engineered Plastics

Comprehensive offerings of plates, foils, round bars, tubes and profiles, coupled with state-of-the-art machinery, ensure top-tier products in every size and scale.

Empower Your Product and Material Selection with ERIKS

Informed Decisions Begin with Detailed Data

Selecting products and materials for critical H2 applications requires more than just general specifications.

At ERIKS, we provide:

Data Sheets: We provide an extensive range of products and materials that are rigorously tested, and we present these results in comprehensive data sheets. From basic material properties to complex performance analyses under varied conditions, you have access to all.

Relevance to Real-world Scenarios: Our testing does not operate in a vacuum. We simulate real-world scenarios to ensure that the data you get is not just theoretical but also applicable.

Support for Custom Queries: Have a specific test condition in mind? Need data for a custom product? Our team is on standby to assist with custom requests, ensuring you always have the insights you need for your unique applications.

Comprehensive H2 Material Testing

In a dedicated laboratory, fully certified to test materials for hydrogen applications, our rigorous and integrated approach encompasses:

Mechanical Testing: Assessing the durability, strength, and resilience of materials in a hydrogen environment.

Chemical Analysis: Determining the compatibility and reactivity of materials when exposed to hydrogen.

Every test we conduct is anchored in precision and ensures that your materials are perfectly suited and safe for hydrogen use.

Tailored Hydrogen Solutions for OEMs

ERIKS pioneers in designing custom H2 solutions for power (OEM) Machine Builders. Our engineering labs seamlessly transition from idea to tangible components, using Design for Six Sigma principles.

Our expertise encompasses material compatibility, H2-specific resistance parameters, and more:

Fast-Track H2 Prototyping

We employ rapid prototyping to convert designs into real-world prototypes efficiently, covering everything from initial configuration to final series production.

Advanced 3D Printing for H2

Using advanced tools, ERIKS crafts and refines prototypes and components central to hydrogen power. We streamline the transition from design to physical H2 parts, accelerating OEM power solutions.

FEA for Optimized H2 Design

Bypass conventional field testing; our Finite Element Analysis (FEA) digitally assesses hydrogen components under operational stresses. This precision ensures H2 readiness for your applications and reduces development time.